Etching metal components

(Advanced Chemical Etching)

Cumatrix is an agent of ACE, Advanced Chemical Etching. ACE is specialised in etching metal components.

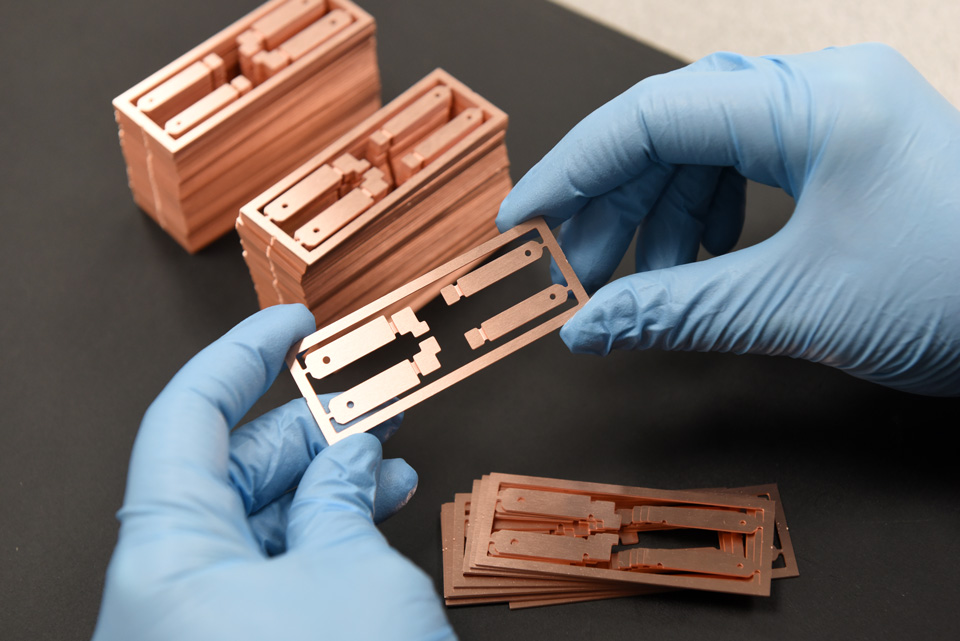

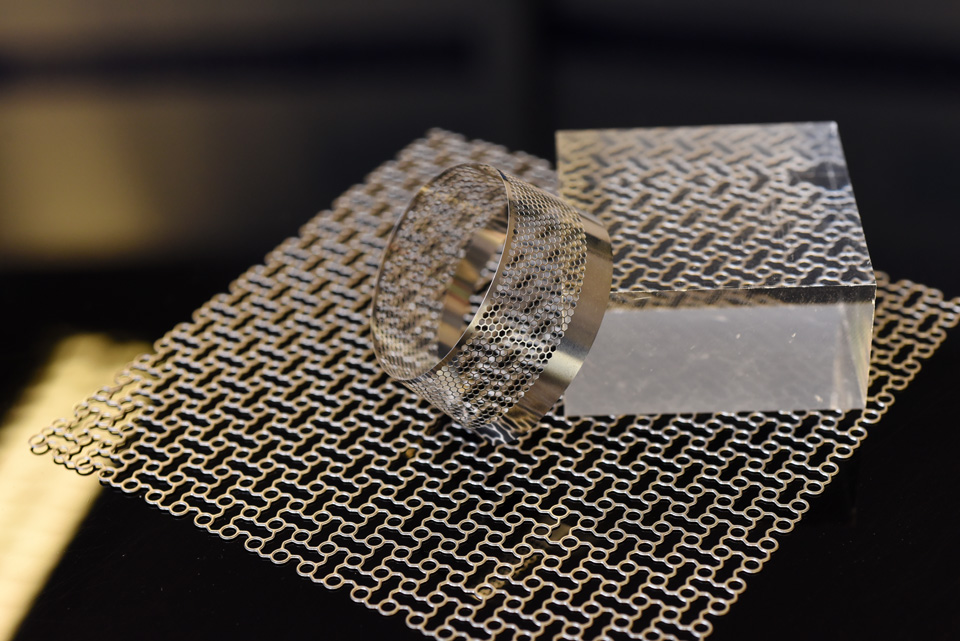

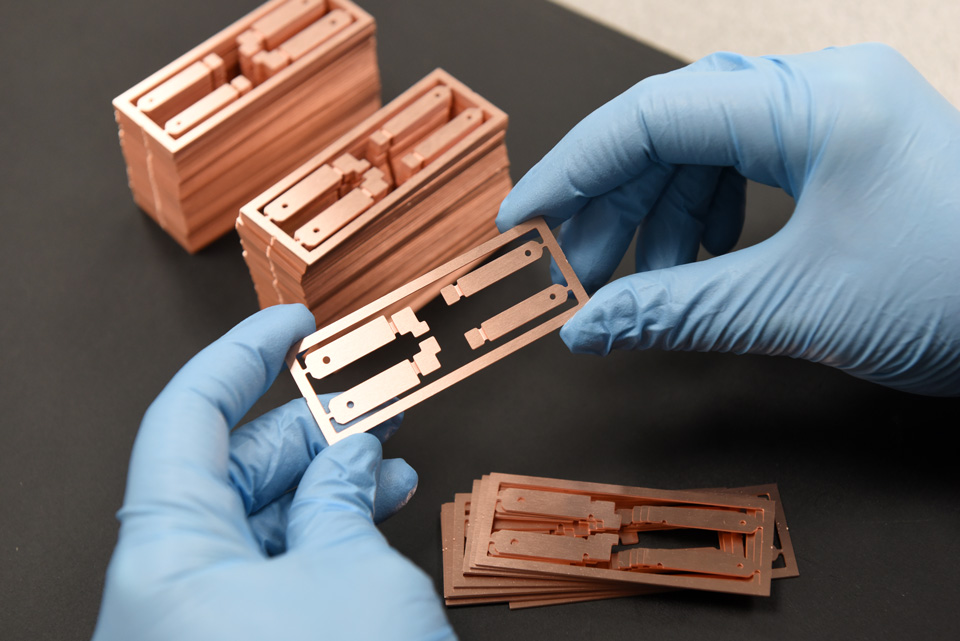

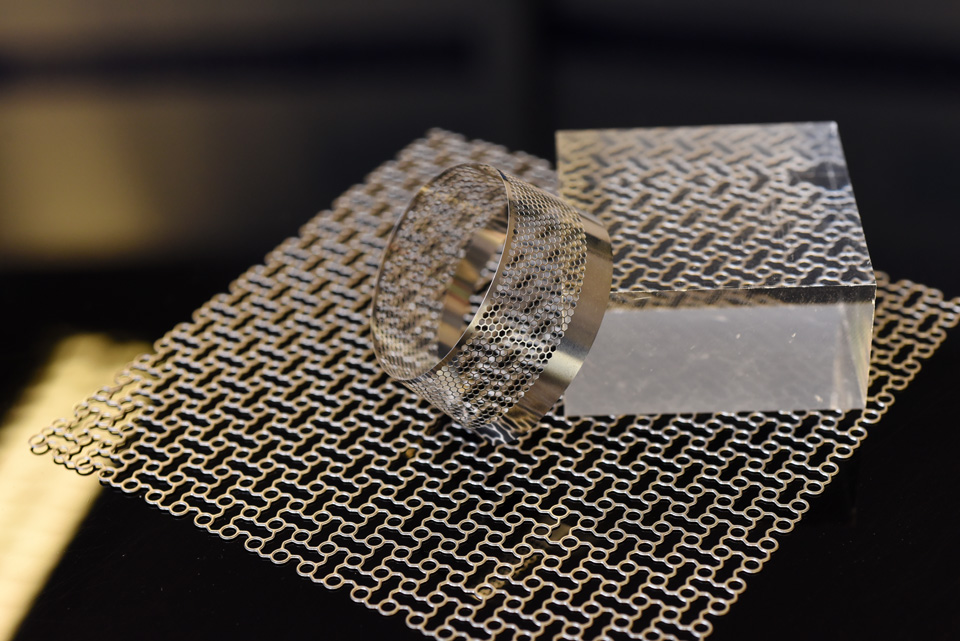

ACE is a company specialised in etching and forming metal components from 80 micron to 1.5mm in thickness, and is established in the United Kingdom. The etched forms can be provided with a galvanic top layer.

Cumatrix is ACE's agent and can help you with the design, etching and forming of your product. Your design can also be provided with different finishings, including plating and passivation. Thanks to our high-quality service and additional options you can save a great deal of time and effort.

Do you want to have a metal component etched, and possibly formed afterwards?

Contact us for more information or

request a quote. We’re happy to give you an affordable quote. The delivery period depends on your choice of material, the finish and the complexity during the realisation of your product. To receive a quote for chemical etching, submitting a PDF file suffices.

Request a quote

What is chemical etching?

Chemical etching is an advanced, very precise technique to etch metal components. Special compound acids are used with which most metals up to a thickness of 1.5 mm can be etched. Even complex metals with special characteristics can be chemically etched.

The supplied design is applied to a film using a laser printer to create a photo tool. After cleaning the metal, a coating is applied, onto which the photo tool is placed using UV light. The board then goes through the etching machine. Any metal not covered is removed by the etchant. When the board comes out of the machine, the parts are checked based on the customer's data. The photoresist is removed from the board, and the components are broken out of the panel. During the inspection, all components are checked. Following approval, everything is packaged and shipped to the customer.

Benefits of photo etching

What are the possibilities?

After receiving a PDF file, we will make a quotation. We need a dfx file for the production of your part.

- Chemical etching of almost all kinds of metals including steel, nickel, copper, aluminium and titanium.

- A wide range of plate sizes, thicknesses, finishes and quality.

- Special types of metal are also possible. Ask our specialists.

- Different etching profiles are possible to produce different properties such as sharp cutting edges, conical openings and fold lines.

ACE Capability datasheet

Why chemical etching?

Chemical etching is a cost-effective process that is suitable for making precision components. The etching process does not add heat to the components, which means the parts will never deform.

You can also count on short lead times and a burr-free, detailed delivery of your product. No need to apply logos or identification numbers afterwards via laser marking, this can be done during the etching process.

In which sectors are etched metal components used?

Chemical etching has many popular applications. Chiefly aviation, defence, F1, communications, electronics, medical sector, renewable energy and so many more use this efficient technique to etch, mark and process metals.

Which materials can be etched?

Standard metals such as stainless steel, spring steel, copper, brass and phosphor bronze but also special metals can be etched on request. ACE is specialised in etching aluminium, titanium, nitinol, molybdenum and the like.

Visit the ACE website

ACE, Advanced Chemical Etching, holds the following quality certificates:

- ISO 9001 Accreditation Certificate

- ISO 14001 Accreditation Certificate

- AS9100 (Quality)

- IATF16949 (Automotive QMS)

- ISO 13485 (Medical QMS)

Every year, you will find us and our ACE colleagues at the

Precision Fair in the Netherlands. Come visit us and find out more about the chemical etching of metal components.

Do you want to find out more about the various possibilities for your project? Don't hesitate to

contact us.